Vibration Meters

Vibration Analyzer VA-14NEW

Features

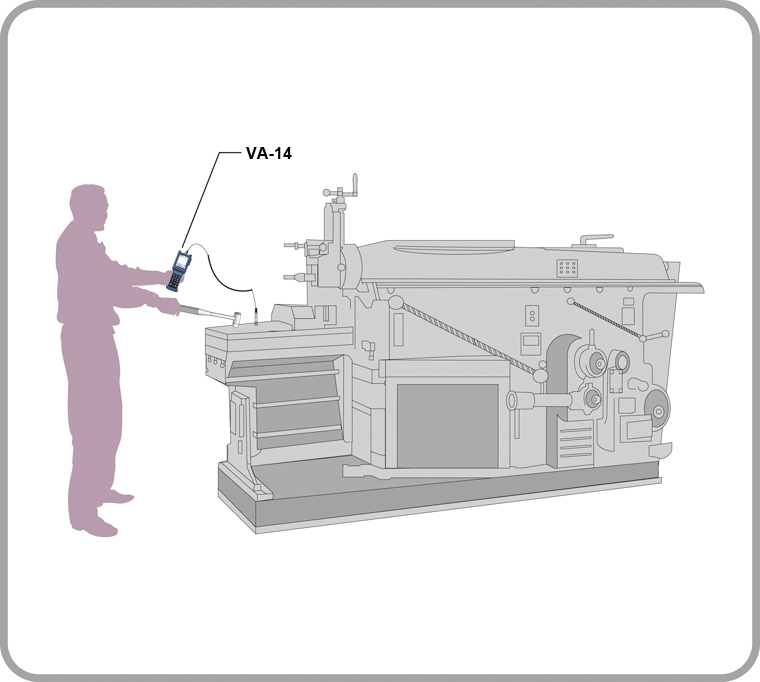

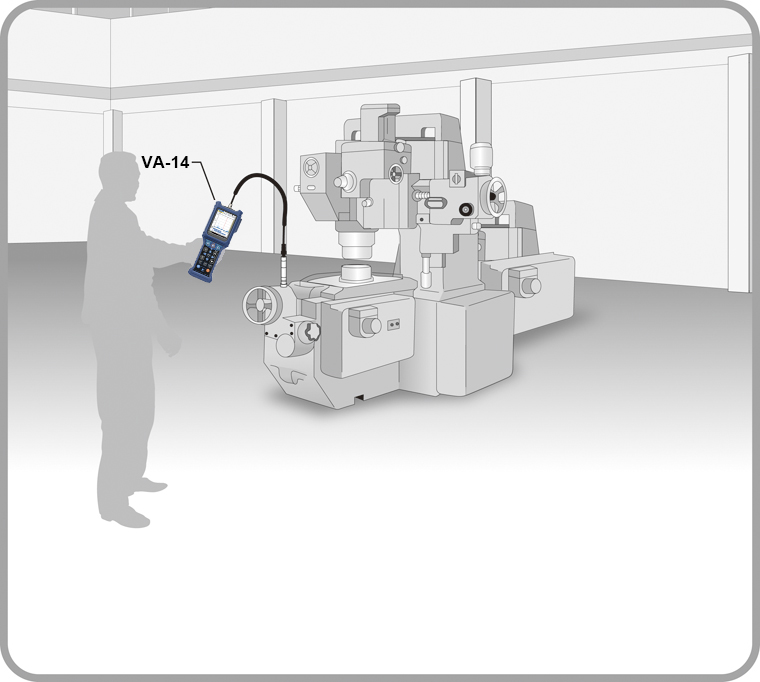

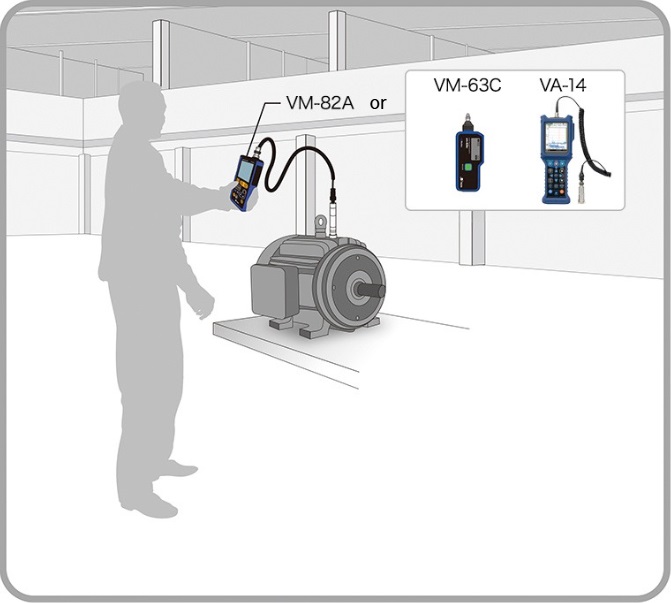

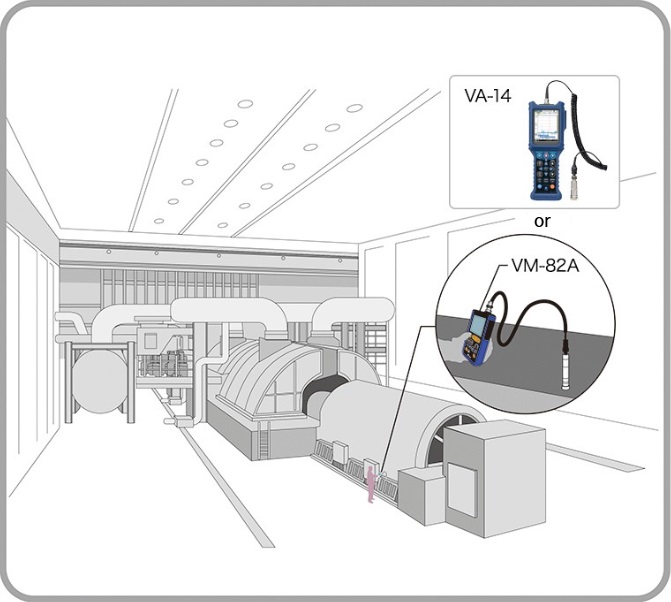

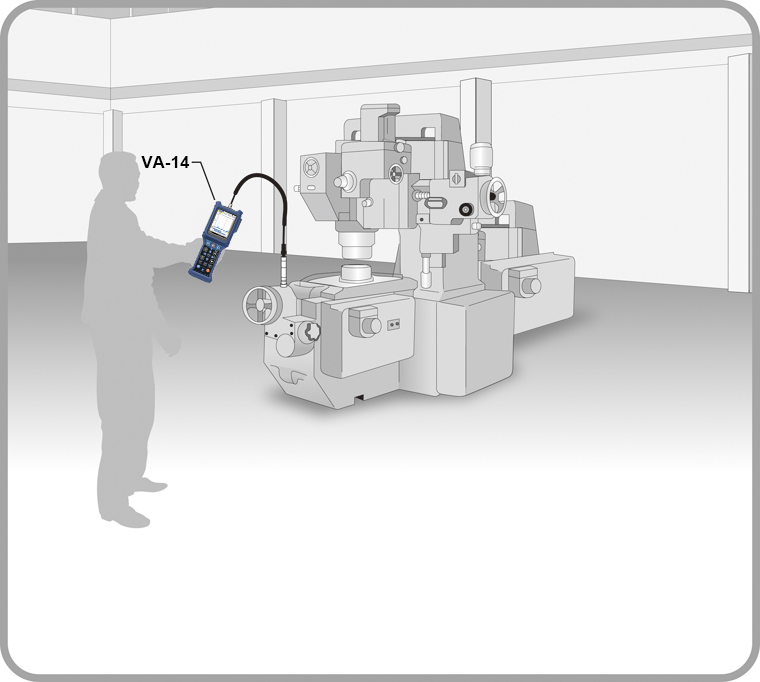

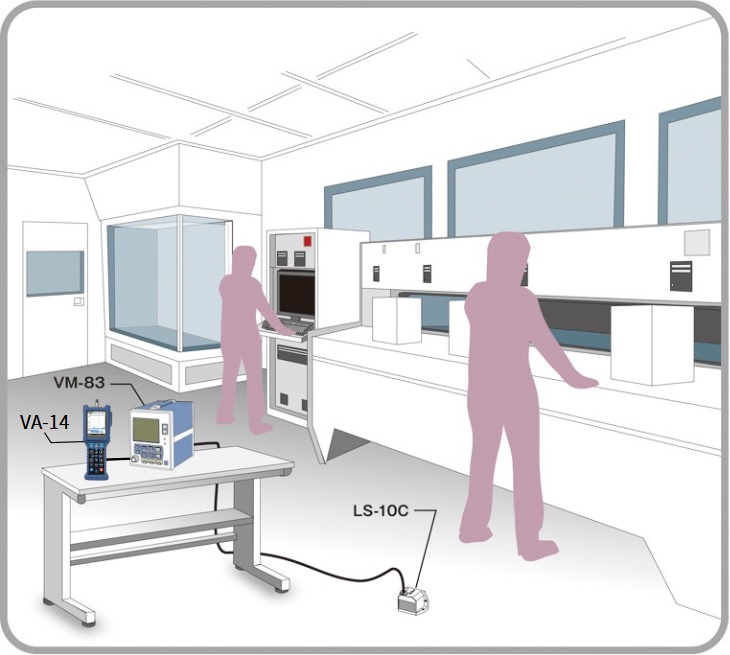

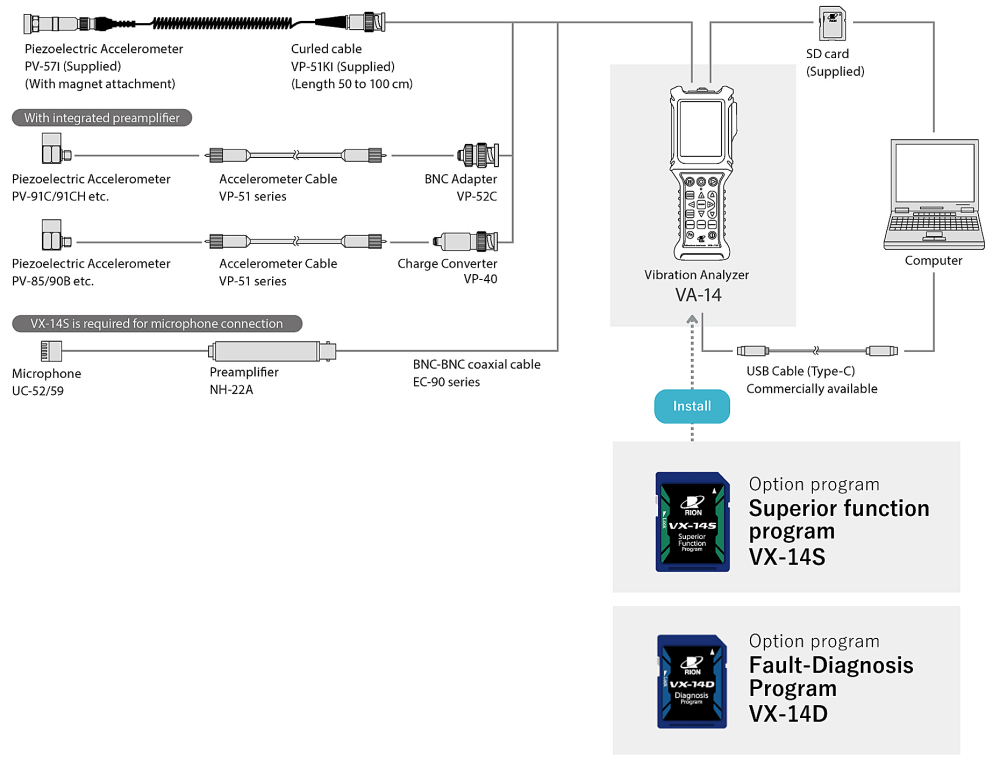

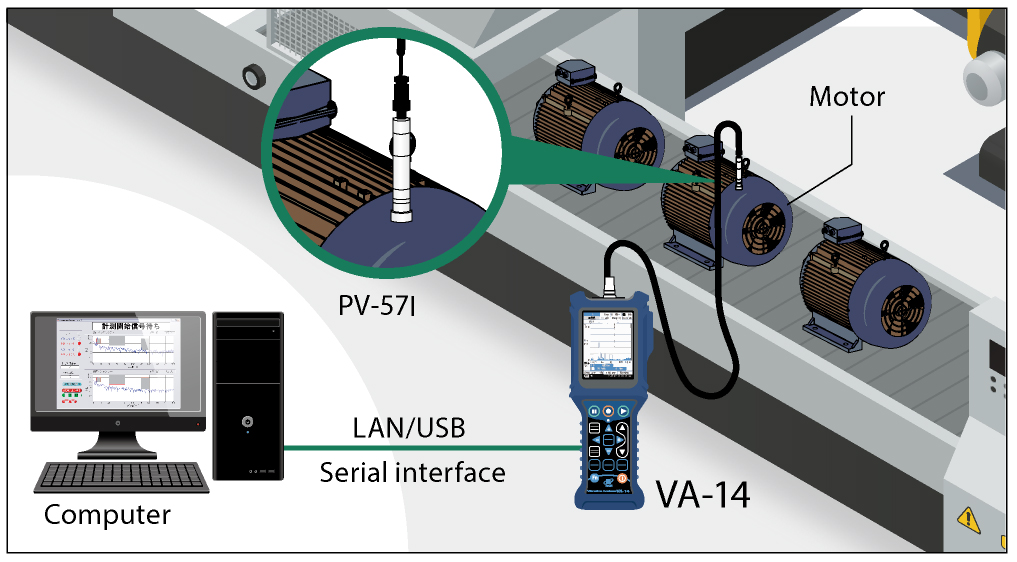

The VA-14 is a Vibration Analyzer with FFT analysis function that comprehensively includes the functions required for equipment diagnosis and on-site measurement. It is approx. 200 g lighter than the previous model VA-12 and becomes thin in shape, making it easier to hold with one hand. The new LAN terminal strengthens the connection with communication devices, allowing command control of the instrument and file transfer remotely. In addition, by installing the optional program VX-14S, it is possible to connect a microphone and measure sound. As a result, the VA-14 covers can cover not only vibration measurement but also sound frequency analysis and evaluation. It can be used in a variety of measurement situations, including measuring vibrations emitted by rotating objects such as machinery and motors, equipment diagnosis using vibration, and product research and development.

-

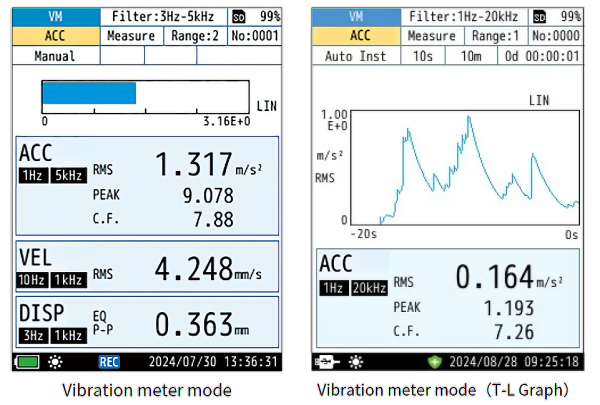

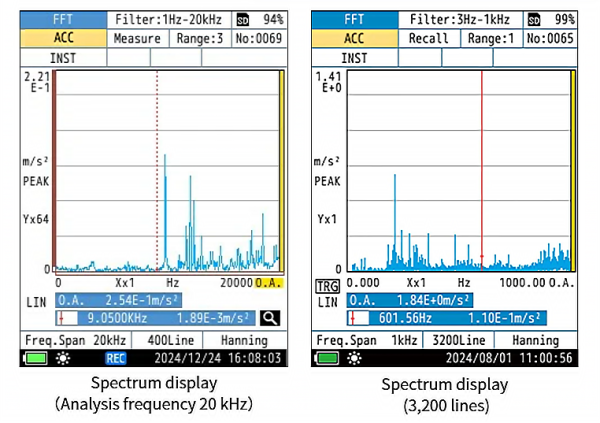

Ideal for equipment diagnosis and on-site measurements

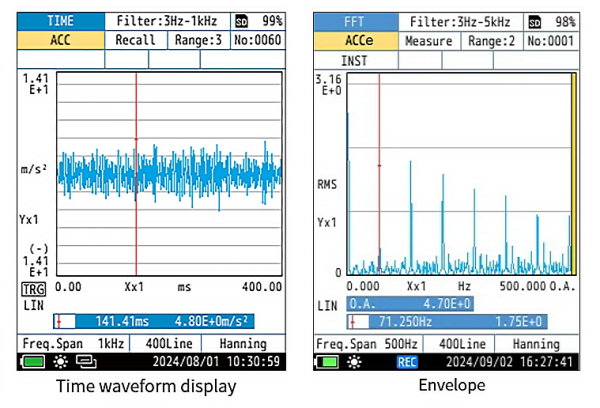

In addition to vibration measurement, it is also possible to perform frequency analysis, allowing for advanced analysis from simple diagnosis to precise diagnosis.

-

Connect to the network(LAN)

Equipped with a LAN terminal to enhance connectivity with communication devices. Measurement data can be used to build a pass/fail evaluation system for production lines. *with optional VX-14S

-

Sound Measurement

Allows sound measurement by connecting a microphone. Covers both vibration and sound evaluation with just one VA-14 unit. *with optional VX-14S

Video

-

Promotion Video

Standard features

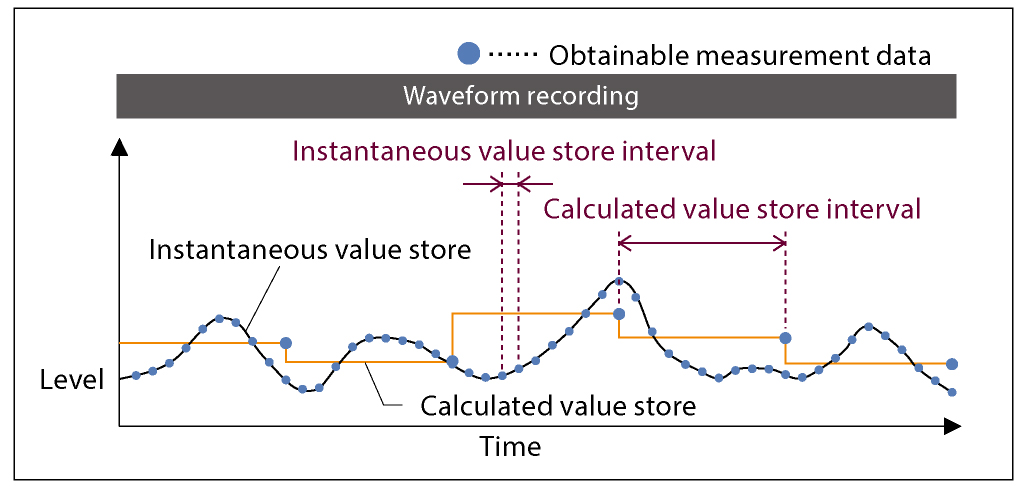

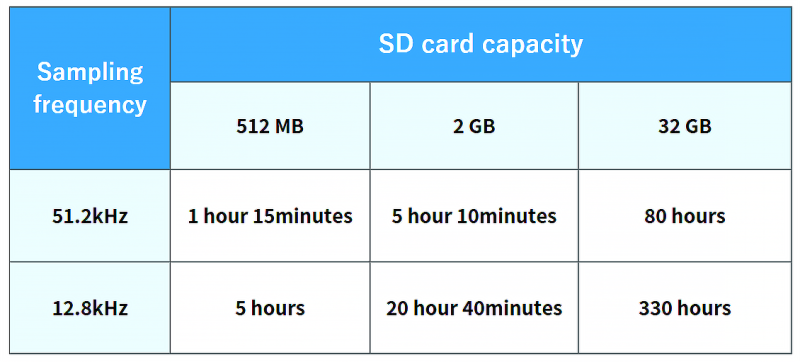

●Waveform recording (Vibration waveform data is saved simultaneously with FFT analysis)

The duration of the recording time depends on the average count.

Up to 1 MB can be recorded.

For an estimate of the maximum recording time, please refer to the table below.

On-site calibration using the calibration exciter VE-10 <NEW>

In addition to inputting the sensitivity value on the sensitivity sheet attached to the accelerometer, the sensitivity can be adjusted using the calibration exciter VE-10. Knowing the correct sensitivity will result in more accurate measurement results.

Superior function VX-14S

Allows sound measurement by connecting a microphone.

Covers both vibration and sound evaluation with just one VA-14 unit.

Usage Examples:

FFT analysis separates noise and vibration. This can be used to evaluate

the quietness of machines, detect abnormal noise, and consider

countermeasures.

(vibration value, time waveform, FFT analysis value).

● Continuous acquisition of instantaneous values

(vibration value: 100 ms, FFT analysis value*).

(vibration value: calculation cycle 10 s/1 m/user setting, FFT analysis value: after calculation).

*Available when connected to LAN.

*Software for the computer is required separately.

◆Long time vibration recording (Operates in vibration meter mode)

[Auto store function]

at the same time.

Records vibration waveforms in WAVE format.

(Select one from acceleration, velocity, or displacement.)

Maximum recording time: 200 hours

conditions, such as the rotational speed of equipment and pump water

volume are changed.

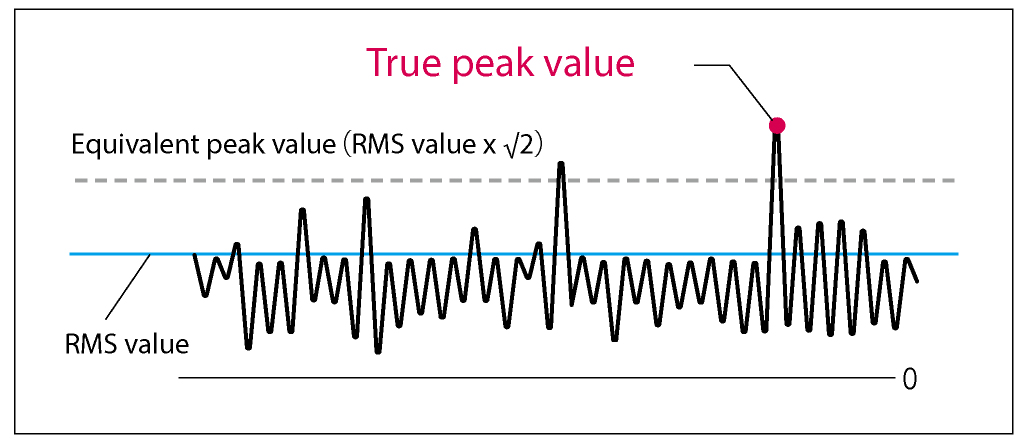

Calculates true peak values not only for acceleration but also for velocity and displacement.

improving production efficiency.

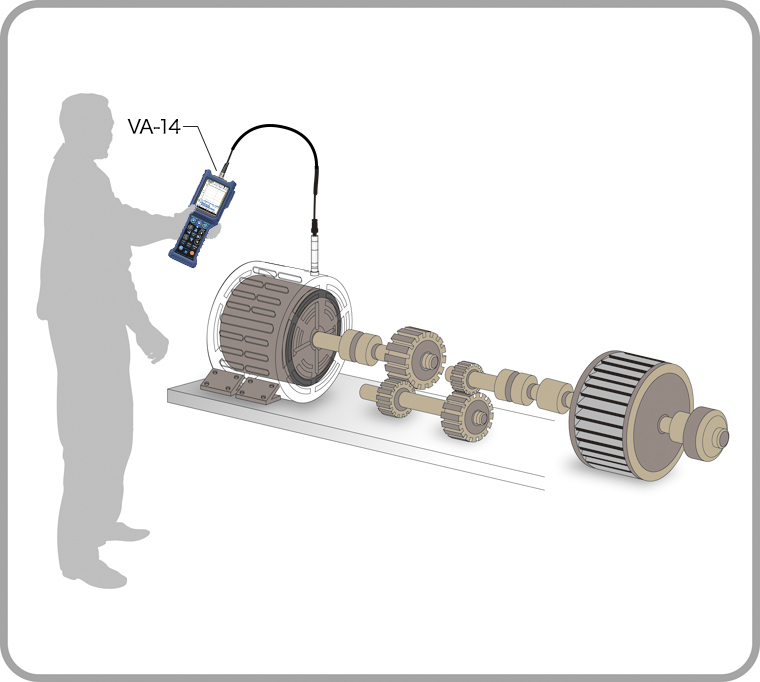

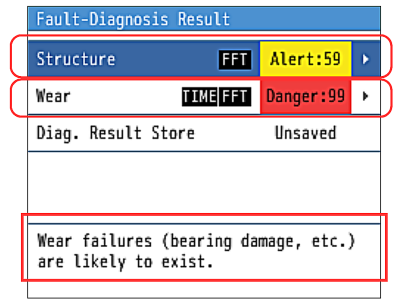

Fault-Diagnosis VX-14D

◆Fault-Diagnosis Function

● Evaluates fault levels using vibration waveforms and FFT data for structural

(unbalance, misalignment) and wear faults (bearings, gears).

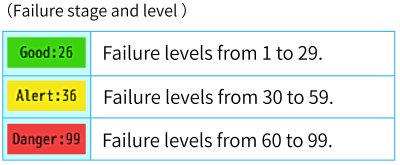

● Rates fault levels from 1–99 and displays/saves 3 stages: Normal, Caution, Alarm.

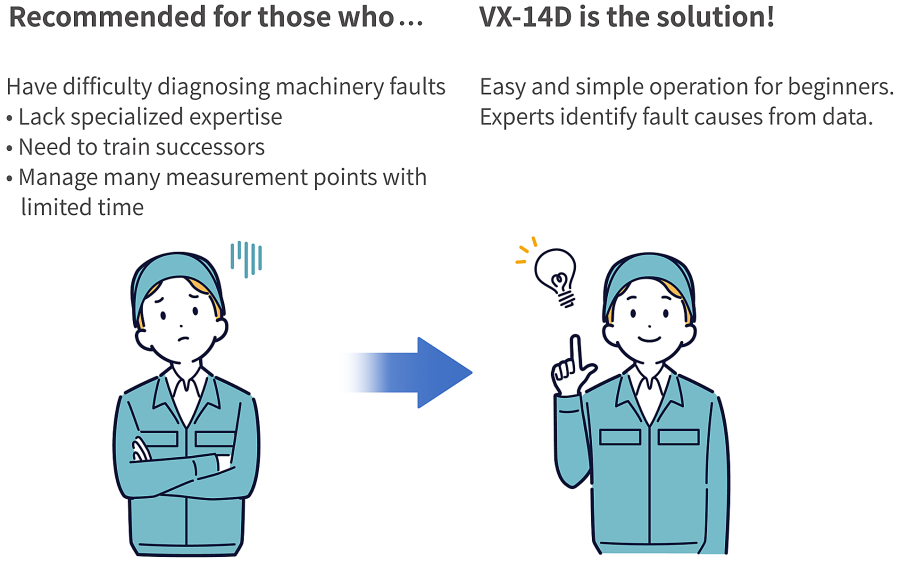

① Simple Operation

— Just Install the Sensor and Start the Diagnosis

The VX-14D replicates the expertise of skilled engineers.

Anyone can perform fault diagnosis easily and quickly, without specialized knowledge.

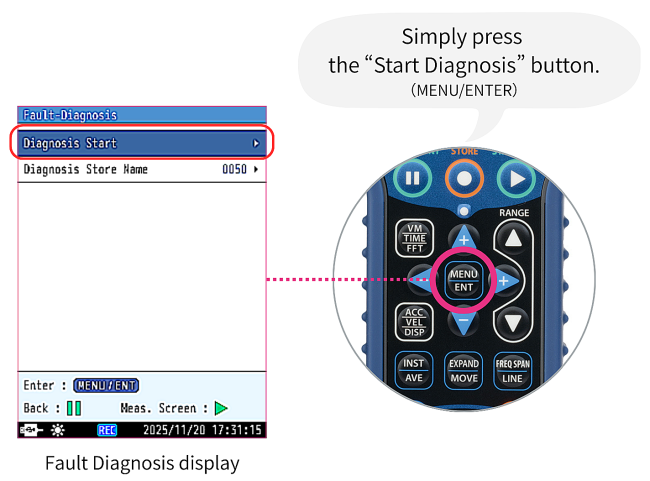

1. Diagnosis Workflow

2. Diagnosis Completed Instantly!

The results and comments are displayed immediately.

Both the fault stage and fault severity level are shown.

* Diagnostic Conditions : Rotating machinery (rotational speed: 180‒3,000 rpm)

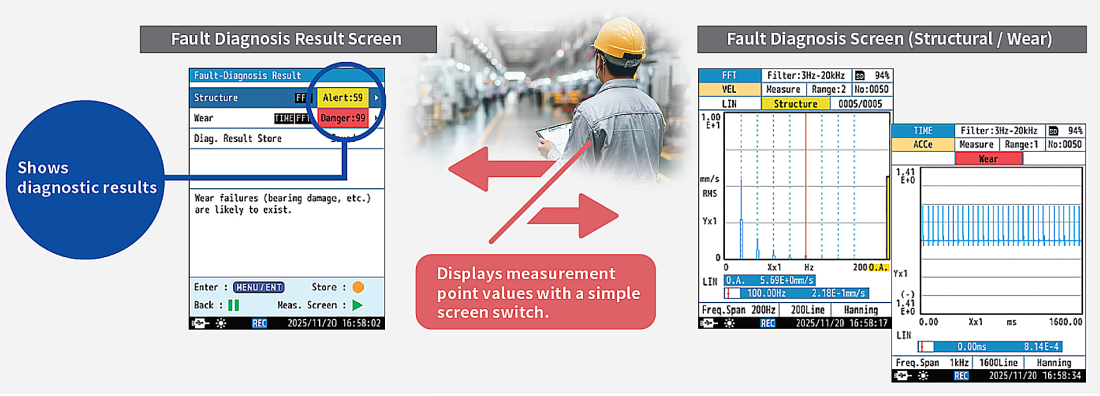

② Measurement Data Supporting the Diagnosis Available

In addition to the automatic diagnostic results, measurement data, including FFT and waveform results, can be reviewed to support expert perform more in-depth analysis.

<RION’s Diagnostic Solutions — Structural / Wear Fault Diagnosis>

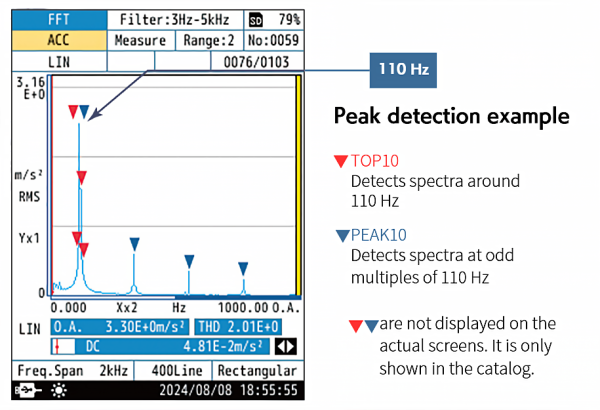

How is the diagnosis performed?

★ Structural Fault Diagnosis:

Diagnoses structural abnormalities such as unbalance, misalignment, and looseness.

When an abnormality is present, the vibration velocity at rotational frequency increases.

VA-14 determines abnormalities based on the magnitude of FFT spectrum results.

It also identifies rotational frequencies for a comprehensive diagnosis.

★ Wear Fault Diagnosis:

Diagnoses abnormalities in bearings and gears.

In normal machines, the vibration acceleration envelope follows a nearly normal amplitude distribution.

When abnormalities occur, there is significant deviation from this distribution.

VA-14 determines wear-related abnormalities based on these differences in the distribution.

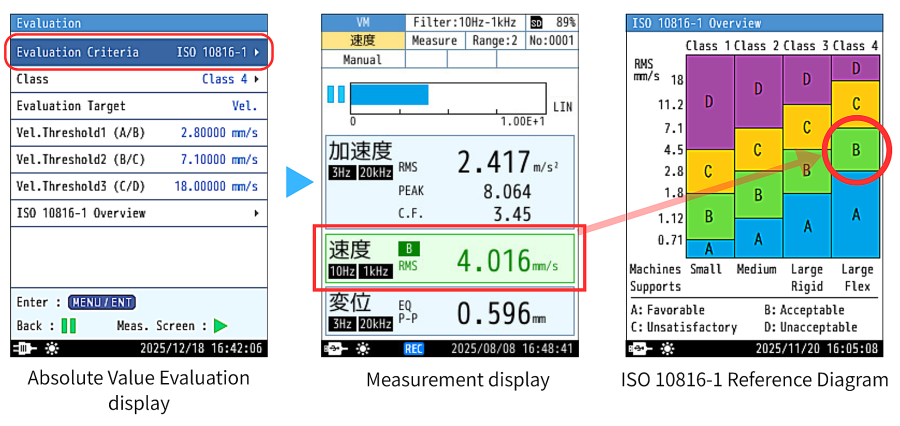

By setting thresholds, machine condition is visualized

with color coding for early fault detection.

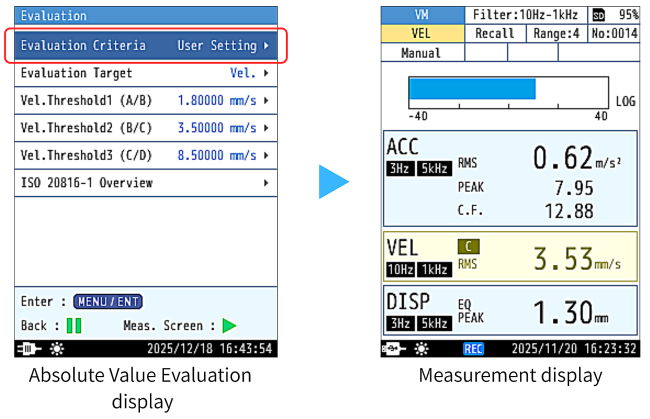

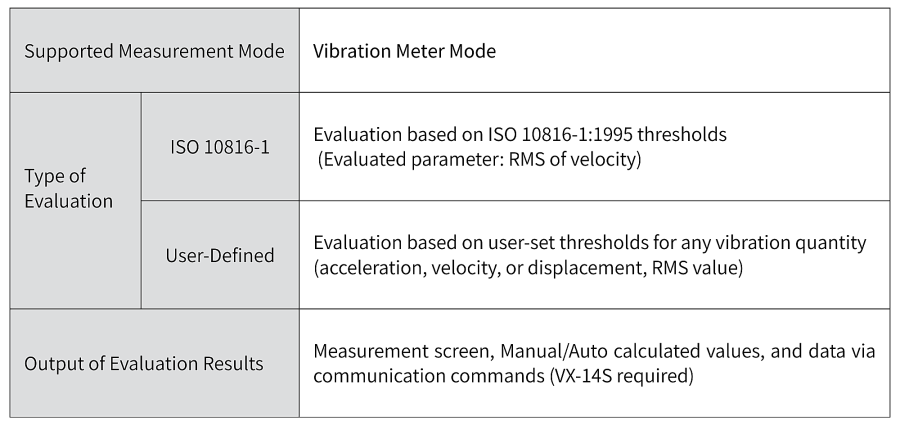

● Absolute Value Evaluation: Supports ISO 10816-1 criteria and

user-defined thresholds based on ISO 20816 series

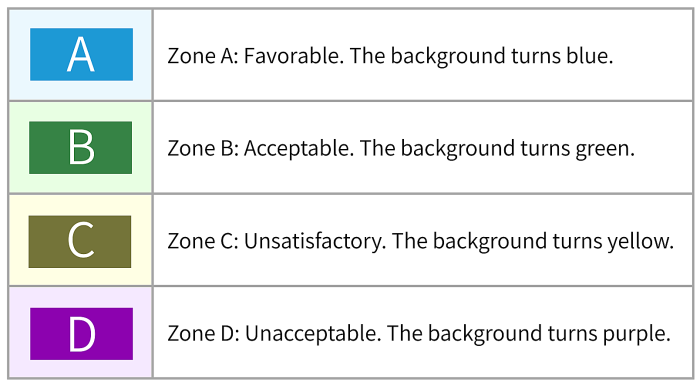

● Color-coded display in four levels according to vibration level:

A: Good / B: Acceptable / C: Caution / D: Abnormal

Color-coded results (A: Blue, B: Green, C: Yellow, D: Purple) on the Vibration Meter Mode screen

allow quick condition checks and are saved with measurement data.

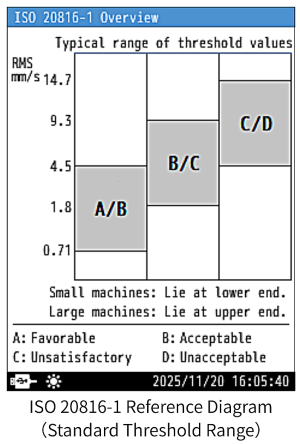

① Reference Values Based on ISO 10816-1

・Evaluation follows the zone criteria defined in ISO 10816-1

(A: Good, B: Satisfactory, C: Unsatisfactory, D: Unacceptable).

the ISO 10816-1 threshold values, enabling easy evaluation without complex operations.

<Machine Classifications for Evaluation>

・Class 2 (Medium) : Motors 15–75 kW; machines ≤300 kW on rigid foundations

・Class 3 (Large, Rigid) : Large machines on heavy, high-rigidity foundations

・Class 4 (Large, Flexible) : Large machines on flexible foundations

(e.g., ≥10 MW turbo-generator sets and gas turbines)

② Custom Reference Values (User-Defined Settings)

・ Evaluation follows custom threshold values for acceleration, velocity or displacement.

・ Evaluation based on the ISO 20816 series is also supported, allowing users

to set zone thresholds as desired.

■ ISO 20816 Series

The standard covers both rotating and non-rotating parts.

(Evaluation Criteria Values)

B: Suitable for long-term continuous operation

C: Not suitable for continuous operation; limited-time operation only

D: High risk of damage; operation prohibited

■ Absolute Value Evaluation Function Specifications

Applications

Library

Options

Carrying Case (Option)

This is a dedicated case for carrying the VA-14 and other accessories.

It can also store accelerometer and microphone, and is lightweight and durable.

Hand Strap (Option)

Attaching the strap to prevent it from falling makes it easier to hold the VA-14 with one hand, making operation easier.

The strap length can be adjusted.

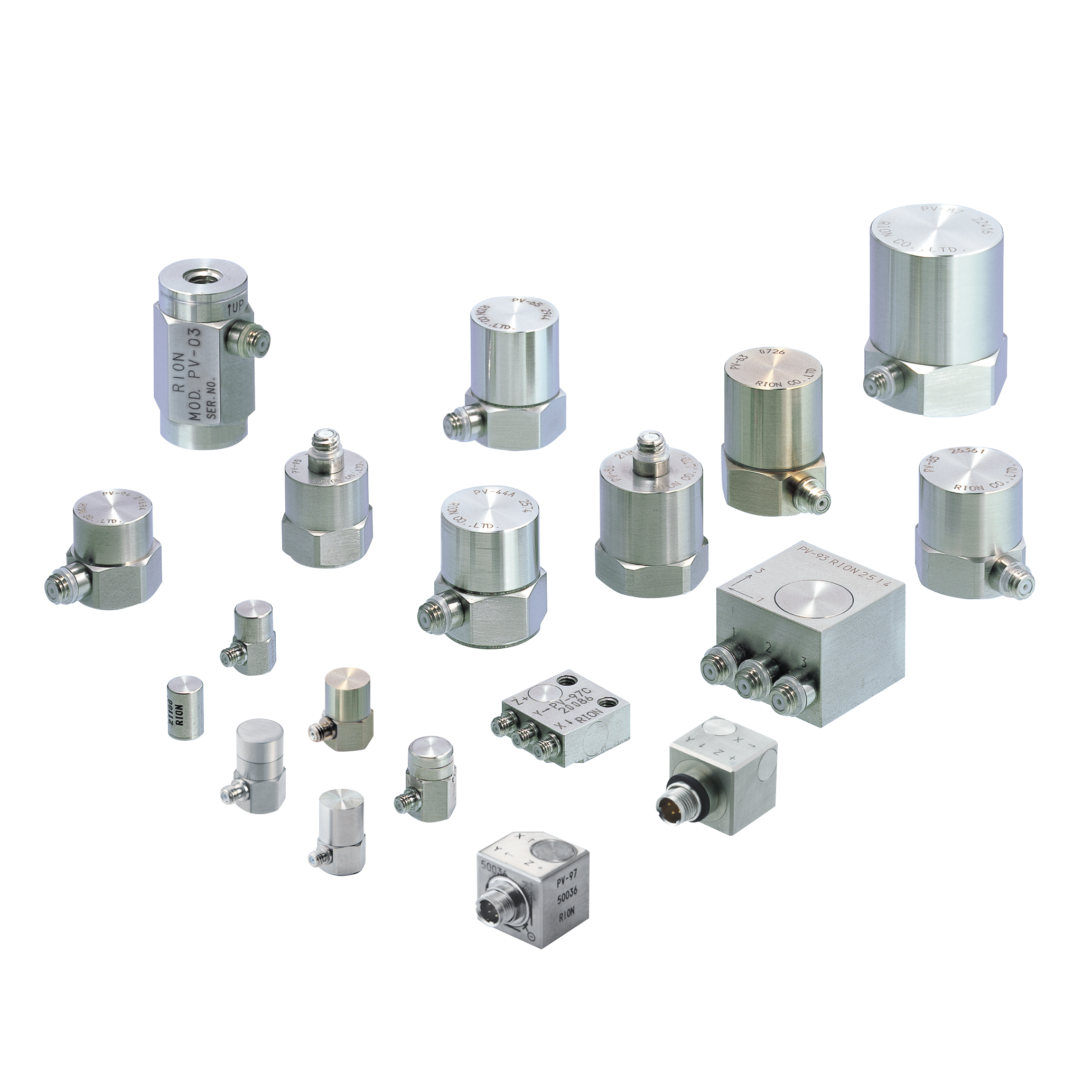

PVseries Piezoelectric Accelerometer

Wide range of products, including ultra-compact, high temperature, 3-axis, and high sensitivity.

It is possible to choose the sensor according to the purpose of measurement.

VE-10 Calibration Exciter

NC-75 Sound Calibrator

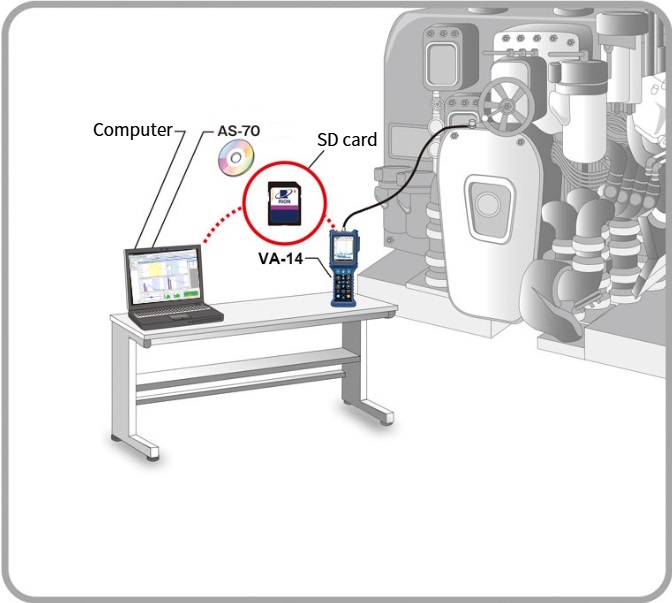

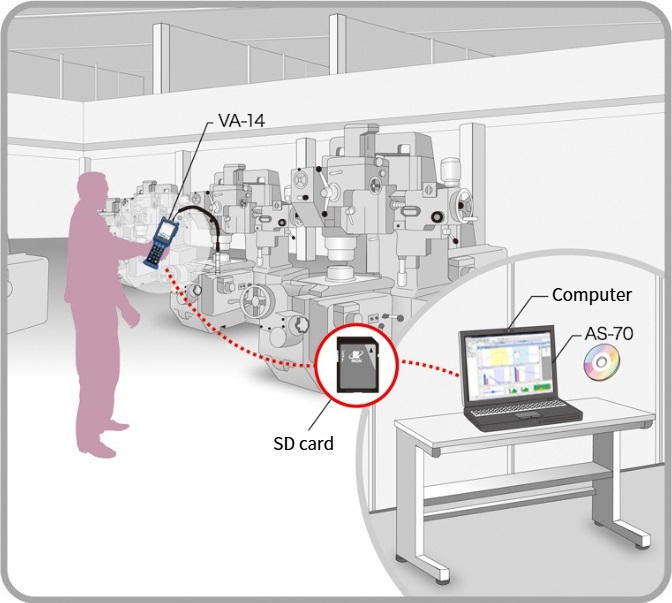

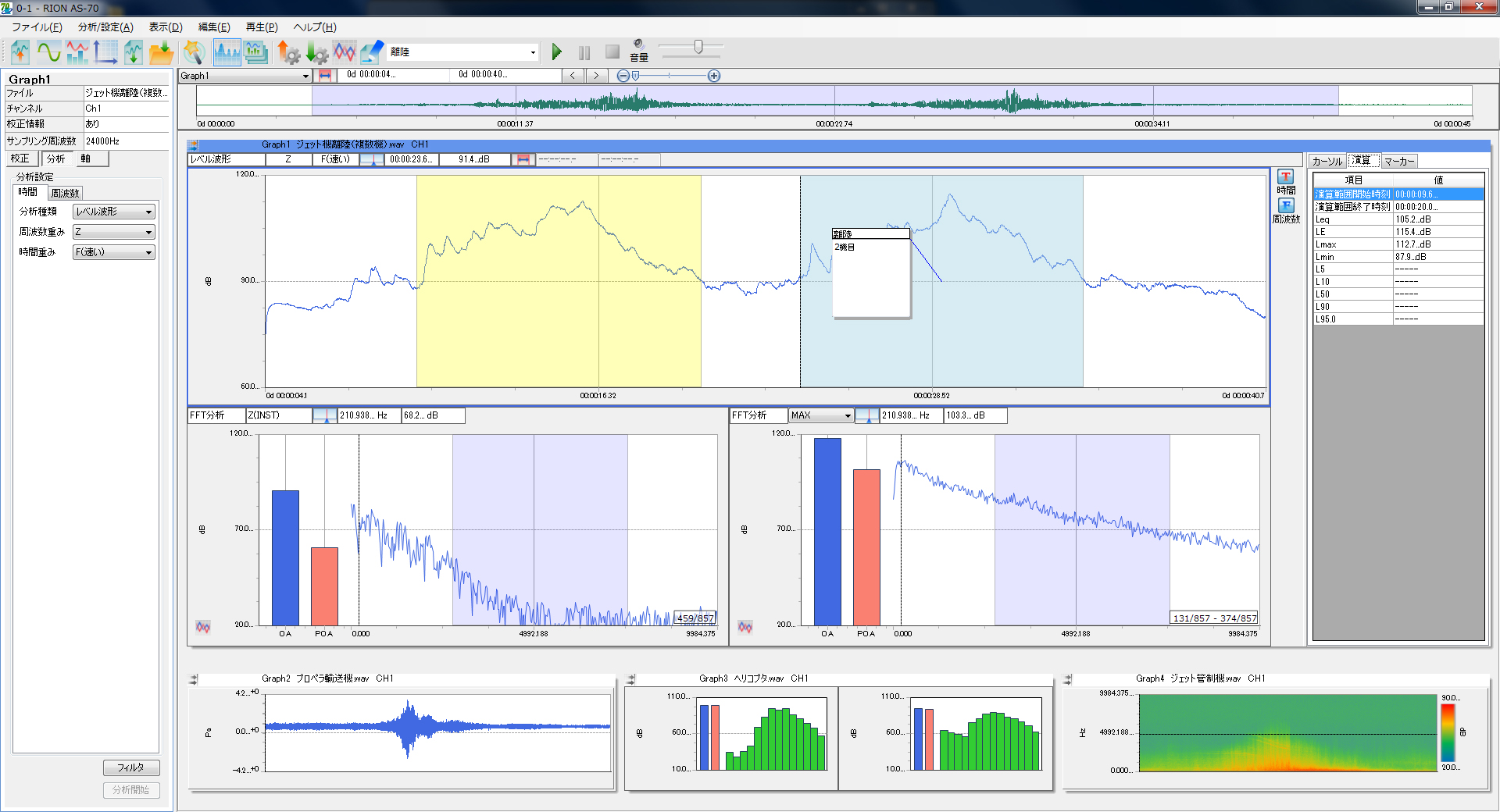

AS-70 Waveform analysis software

Capable of reading WAVE files, graph display, normalization processing, frequency analysis(FFT analysis, octave analysis),

file output, and playback.