VIBRATION AND VIBRATION METERS

Precision Diagnoisis

Precision diagnosis is one of the methods of equipment diagnosis, and is a technology that identifies the cause of the machine abnormality and the location of the abnormality when an abnormality is determined to exist in the equipment using the simple diagnosis described in another section. Frequency analysis is performed to obtain more detailed information from the vibration value determined to be abnormal, leading to the identification of the cause. By understanding the condition of the location where the abnormality is occurring, it is also possible to predict the time until the machine breaks down. It is particularly effective for early detection of abnormalities in rotating machinery.

The Need for Frequency Analysis

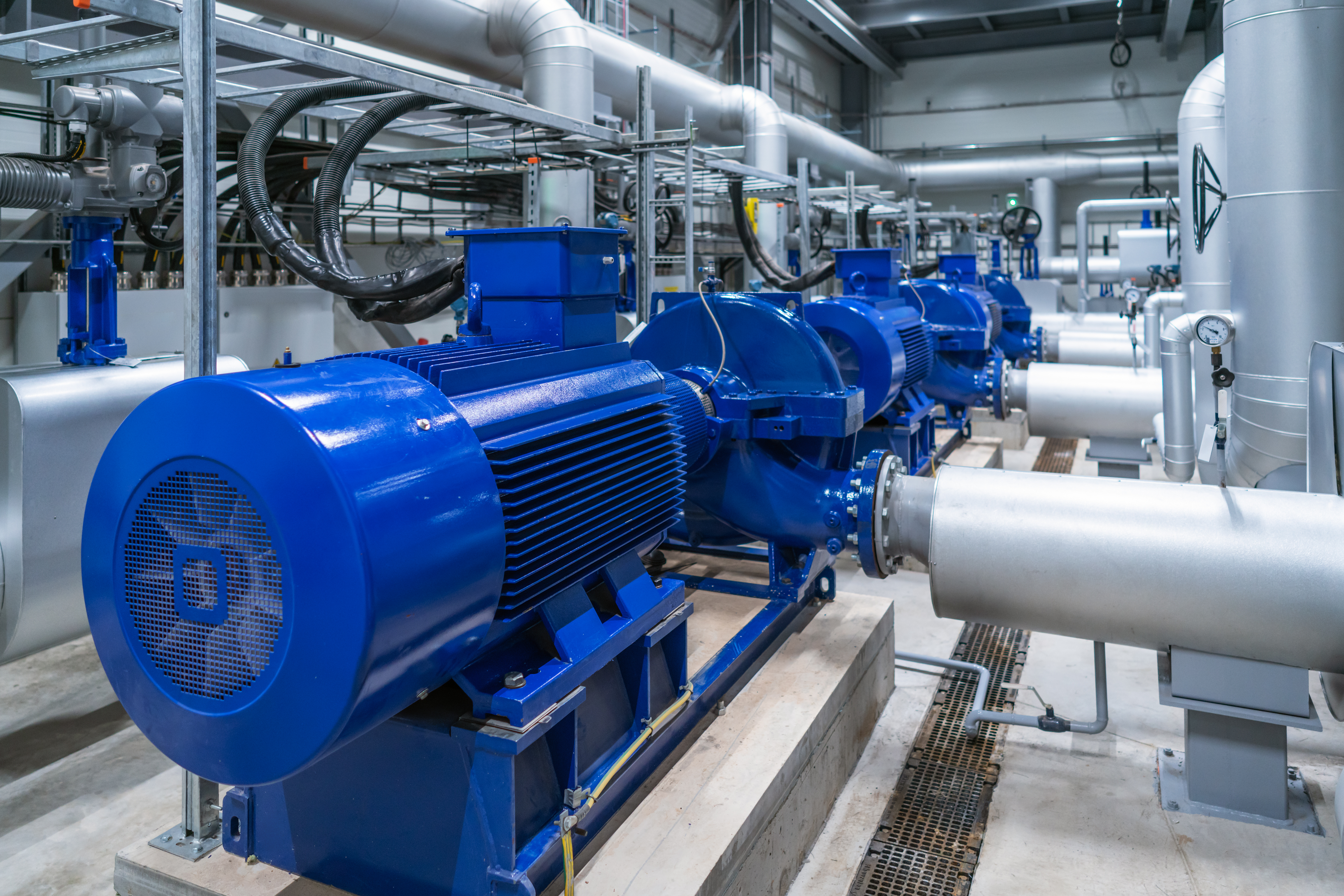

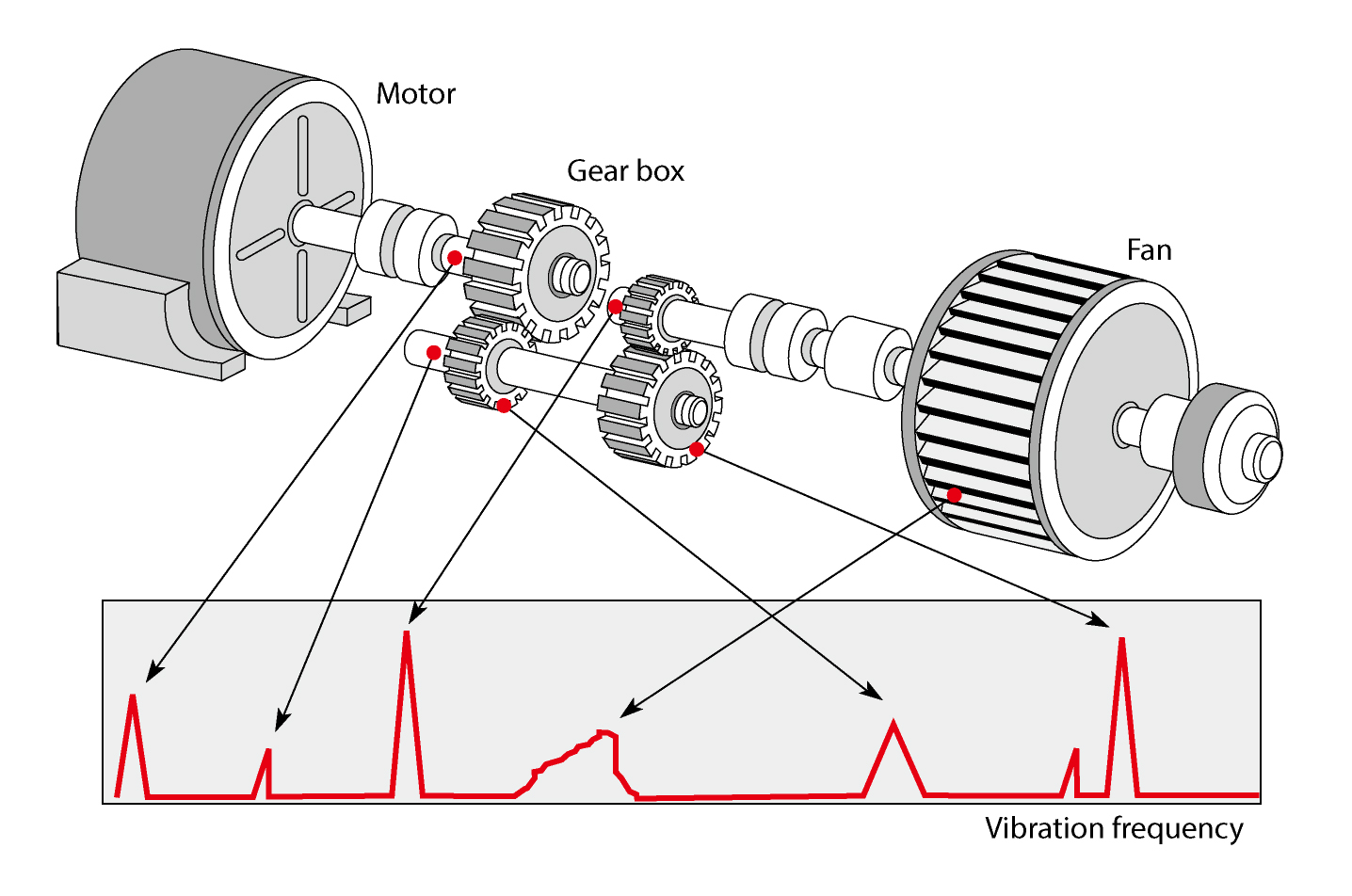

Machinery usually comprises a variety of vibration sources such as motors, gears, bearings, fans, etc. When devising measures to minimize vibrations and when trying to locate the causes of problematic vibrations, measuring only the magnitude of vibrations often will not provide enough information. It is also necessary to perform frequency analysis, in order to determine which types of vibrations exist and what their levels are. As shown in the illustration, the locations where vibrations occur will affect the vibration frequency.Frequency analysis makes it possible to pinpoint vibration sources with greater accuracy.

(Spectra and time waveforms are calculated using a vibration analyzer or frequency analyzer.)

Precision Diagnosis of Rotating Machinery

Precision diagnosis is used to determine the cause of problems as well as the extent, location etc.

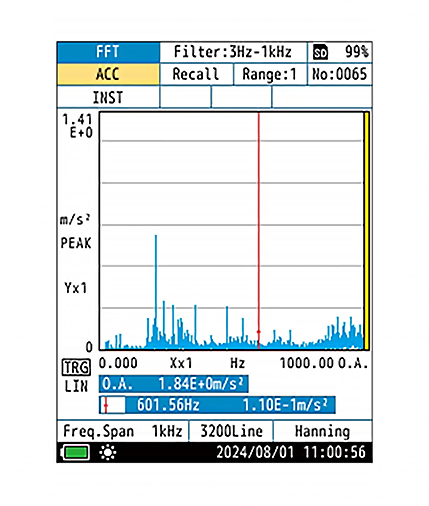

Bearings measurement example

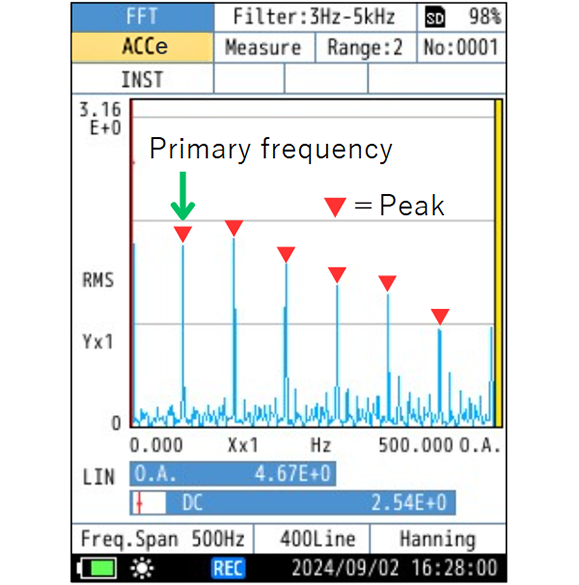

◆Bearings

Bearing problems will cause a significant increase in acceleration values. As seen in the example, envelope analysis shows the peaks at equal intervals. When the size, number of rolling elements, axis rotation speed and other parameters are known, the primary frequency of the lined-up peaks will provide information about the problem location.

*The "▼Peak" and "↓Primary frequency" in the image are for illustration purposes only. They will not be displayed on the actual screen.

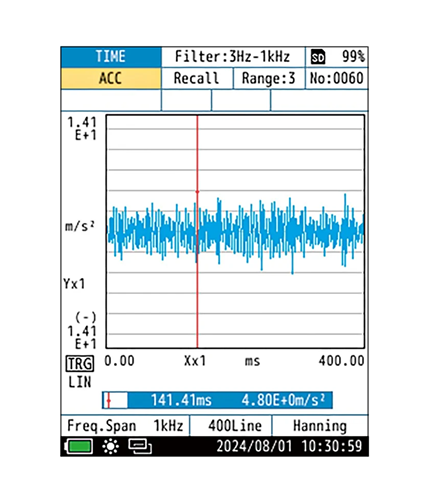

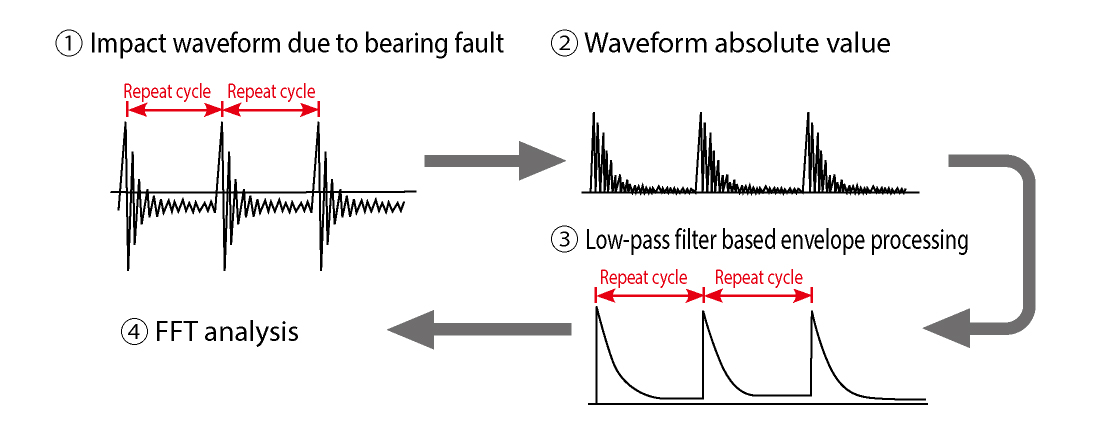

When diagnosing a bearing fault, it is necessary to know the repeat cycle of the impact waveform. This can be achieved by envelope processing, using the principle illustrated below.

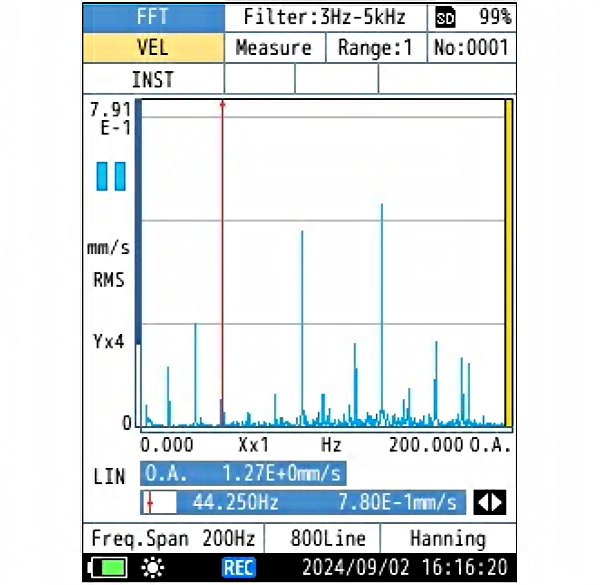

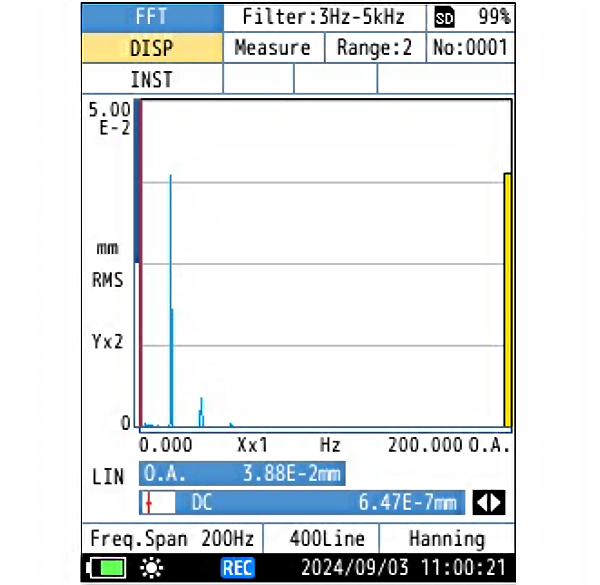

Misalignment measurement example

◆Misalignment

When there is a misalignment, large vibration components that are an integral multiple of the rotation speed will appear in the axis direction. The type of bearing joint affects the multiplication factor. In the example shown here, there are large vibration components with a factor of 3.

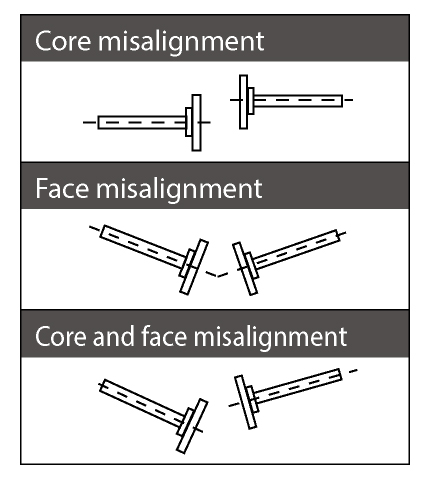

Misalignment explained

When two coupled rotating axes are not properly centered on relation to each other, their centers of rotation will not be in linear alignment. This is called misalignment, which can be either relative to the core or the face or a combination of the two. When misalignment occurs, the thrust load on the bearing increases due to

end face runout, resulting in shorter bearing life.

*Thrust load

It is a force that acts along the centerline of a bearing and occurs when the bearing rotates.

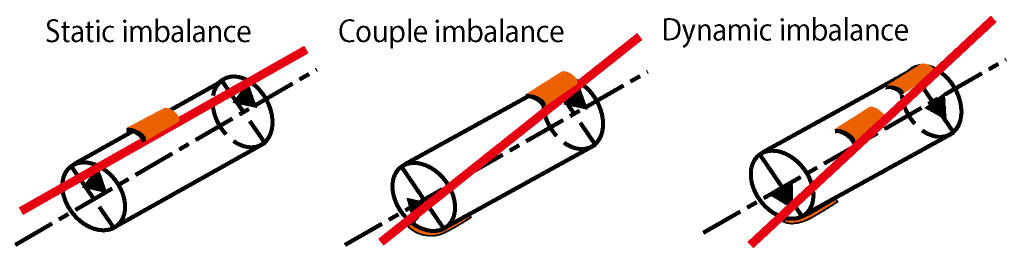

Imbalance measurement example

◆Imbalance

When there is an imbalance, large vibration components at a frequency equal to the rotation speed will appear in the circumferential direction. Vibrations of other frequencies will be largely absent. The vibration amplitude is proportional to the imbalance magnitude. At higher rotation speeds, the vibration amplitude is proportional to the square of the rotation frequency.

This is a condition where the center of gravity of a rotating body has shifted from the center line. There are various types of imbalance, including static imbalance, couple imbalance, and dynamic imbalance. When an imbalance occurs, the load on the bearing in the circumferential direction increases, resulting in shorter bearing life.

Measuring instrument ideal for precise diagnosis