VIBRATION AND VIBRATION METERS

VIBRATION AND VIBRATION METERS

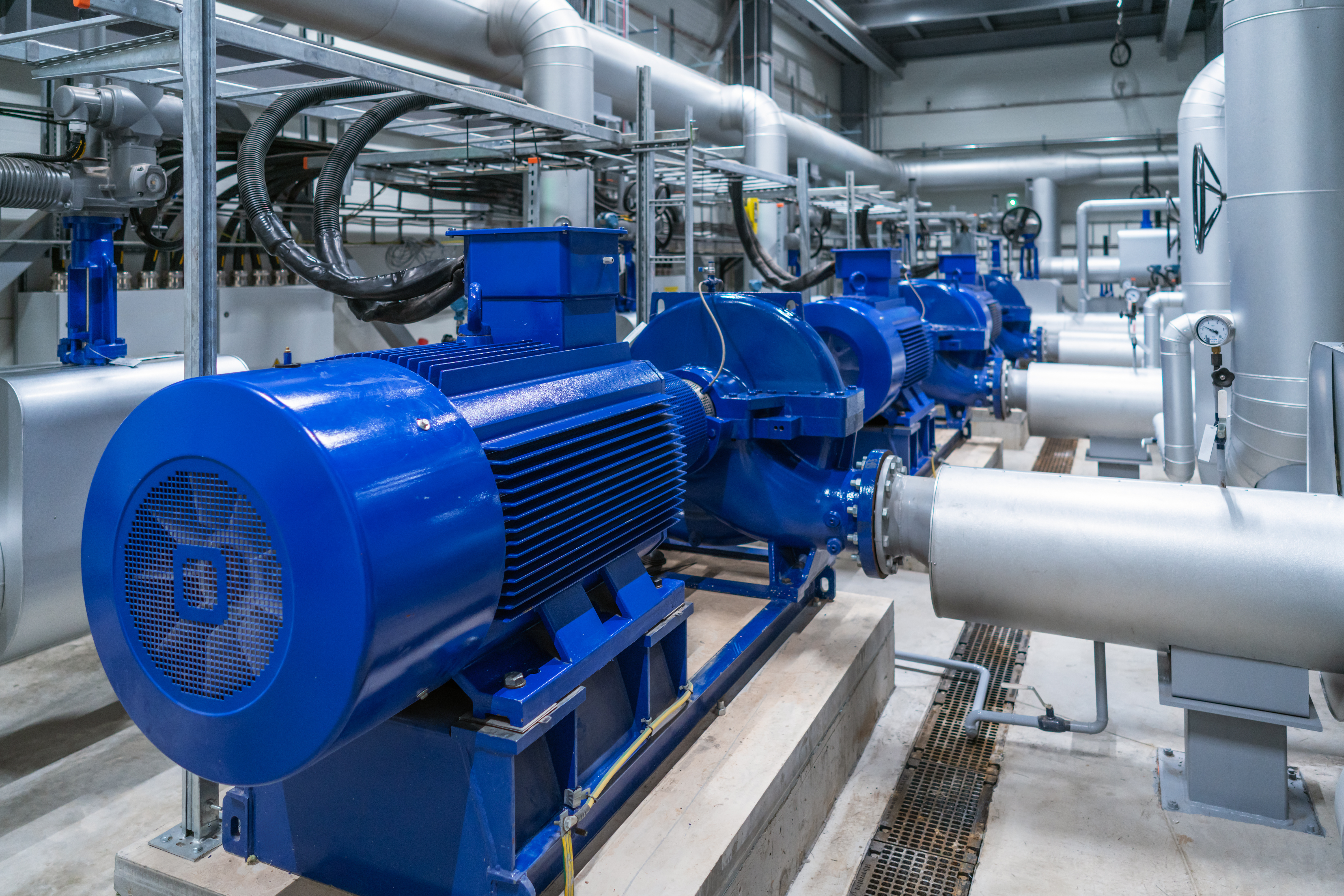

Normally, vibrations arising in an industrial or residential environment are clearly an unwanted phenomenon, except in some special cases. Such unwanted vibrations are not only unpleasant to humans but they can also shorten the life of machinery, impair product quality, and cause defects and breakdowns.

Sound arising from vibrations is also an environmental problem. Finding solutions to the multi-faceted problems presented by vibrations therefore is an important and pressing task.

RION vibration meters are effective tools used to collect information in a wide range of fields. These include the maintenance, monitoring and testing of machinery, product design and research, quality control, noise and vibration countermeasure research, evaluation of tools and vehicles according to labor environment and hygienic regulations, vibration pollution control, and seismographic data collection and disaster prevention.

This article will explain the basics required to perform vibration measurements, focusing mainly on mechanical vibration-related matters, as follows:

- Basic definition and properties of vibration

- Maintenance methods for equipment and machinery (equipment diagnosis), etc.